News -

Kitchen cabinets made easy

Flipping through those home style magazines looking for a dream kitchen? With the use of ETP HYDRO-GRIP toolholders your next home investment might not set you back as much as expected.

A wide selection and customization can easily be reached in today’s modern door and cabinet manufacturing process. The use of high quality hydraulic toolholders enables not only manufacturer´s to benefit from decreased costs and higher efficiency, no - at the same time consumers may benefit from a much wider range selection and freedom of choice.

Unrivaled precision makes for unrivaled selection

In the American heartland of Kansas, Koch & Company, has created a world class door and cabinet manufacturing firm. A dedication to excellence in craftsmanship quality and customer service has made them a leader in the industry. With twenty door styles, eleven stain options and six paint colors, Koch Cabinetry provides you with a vast array of options.

How can that be?

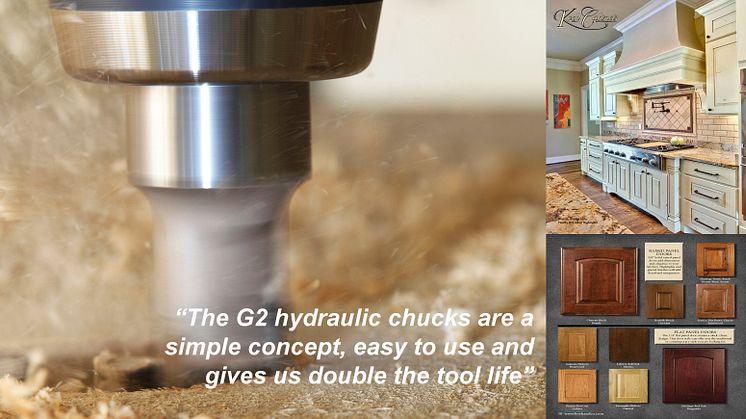

Well for one, after using the ETP HYDRO-GRIP G2 toolholders Koch & Co. experienced a 100% increase in their router bit tool life. Normally running 70-80 sheets before changing bits, now no change is needed until 150-160 sheets, all with the same high quality finish. Secondly the technical changeover from mechanical ER holders to the hydraulic ETP range enables a massive machine downtime decrease, as a tool change now can be performed under 1 minute compared to previously 5 minutes!

Barry Koch of Koch & Company states; “The G2 hydraulic chucks are a simple concept, easy to use and give us double the tool life. We plan to update the rest of our CNC routers with ETP HYDRO-GRIP products.”

ETP Transmission AB is proud to be a partner to Koch & Company and support their efforts to streamline production within the woodworking industry.

Facts on the Koch Cabinet project:

Productivity and Time savings - changing the router bit

Before:

- change after 70 - 80 sheets

- 5 minutes per tool.

- 12 tool changes per day =

1hr of operator time per day

- 260 hrs. a year.

Now:

- change after 150 - 160 sheets

- 1 minutes per tool.

- 6 tool changes per day =

6 minutes of operator time per day

- 26 hours a year.

Result:

- Productivity/machine: +100% !

- Time Savings/machine: 234 hrs/year!

- Same high quality finish!