News -

Deep hole drilling excellence

ETP ECOGRIP ER

- toolholder meeting the challenges of deep hole drilling.

Efficient production of deep holes can present workshops with a number of challenges. To produce a final product of great qualitywhile keeping your costs under control, you must achieve accuracy, repeatability, a good surface finish as well as a reasonable and predictable tool life. Choosing the best drill for the job is one thing, selecting the best toolholder another.

Runout challenge

Deep-hole drilling challenges may include the evacuation of chips as well as correct choice of coolant. However the most important challenge of deep hole drilling is maintaining control of the runout, which increases with cutting tool length. A moreaccurate method of toolholding, using the adjustable ETP ECOGRIP ER holder can help you compensate for the increasing runout from longertools.

Lowered production costs

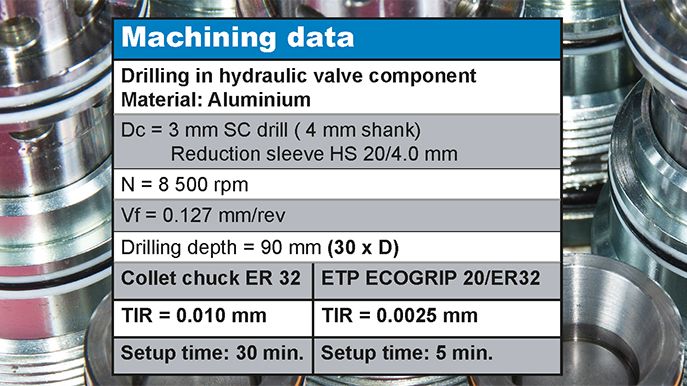

Our customer manufacturing high quality valve components was faced with ever increasing cost due to breakage of expensi- ve drills. Using an ER32/CAT40 collet holder in combination with a 3 mm SC drill with 30xD machining length resulted in bad runout values up to 10 microns. After initial drill setting the runout would increase during turret tool changes. Also every time the drill had to be changed in the collet chuck, the setup process would

start all over again, taking up to 30 min each time.

ETP ECOGRIP ER

With the introduction of the adjustable high precision toolholder from ETP, ECOGRIP ER, tool setup time and changes are now heavily reduced. Tools are set to 2.5 microns of runout within 5 min. Runout accuracy is

maintained after several drill changes in the holder and after drilling over 2 000 holes.

With the help of the 3 adjustments screws in ETP ECOGRIP ER the tool runout can easily and accurately be set within a few minutes. The hydraulic centering and fastening helps to achieve perfect repeatability.

All in all allowing the customer to benefit from improved hole and part quality, eliminated drill breakages resulting in longer tool life, reduced set-up times and lowered production costs!

ETP ECOGRIP ER

Benefits and features

- Compact holder design

- For long over-hang applications -

possibility to dial in the requsted TIR - Quick and Easy handling