News -

In need of precision?

A hydraulic connection with exceedingly high precision and a pressurising mechanism that is designed for at least 1 000 mountings and dismantlers - that is exactly what the hydraulic connection ETP-TECHNO offers. With a rigid design ETP-TECHNO consists of a double-walled hardened steel sleeve filled with a pressure medium and a flange. The flange contains the pressure screw and piston with a dual sealing function - an o-ring including a backup-ring and a steel ball. Because of the great precision, ETP-TECHNO is perfect for applications where fast frequent changes or adjustments are required. Another advantage of the hydraulic connection is the quick assembly; you can mount ETP-TECHNO with just one screw.

– ETP-TECHNO is one of our absolute premium products today. If you compare it to conventional solutions it’s the best alternative, especially if you are short of space. This hydraulic connection has extremely good concentricity and is frequently used in precision gears and test benches, says Peter Kremsl, Application Engineer at ETP Transmission.

What do they say?

Coventry Engineering is a UK-based engineering firm specializing in the manufacture of bespoke tooling solutions. It has been using couplings and hydraulic connection components from ETP since 2012. Here, Paul Pickering, Operations Director at Coventry Engineering, explains how ETP’s expertise has helped them to provide reliable, flexible solutions to better serve their diverse customer base.

When their customers can’t solve a problem with conventional tooling equipment, Coventry Engineering steps in to provide a tailored solution. Often, this means the development of bespoke attachments that can be fitted to a machine to fulfil a specific application. Sometimes, they need an auxiliary component to give them greater flexibility to meet a customer’s needs - and that is where ETP’s coupling devices really add value.

“ETP gives us exactly what we need to fulfil our contracts with our customers,” Paul says. “For example, if an unmanned machine has an automatic tool selection function, where it picks a tool out of its carousel and carries on working, it needs to have automation and alignment built into it. Historically that gave us a problem with our standard attachments, but the ETP components give us increased flexibility by providing 360-degree rotation of our output position relative to where it needs to fit on the machine. For us, it has been the missing piece of the jigsaw that allows us to meet any customer brief.”

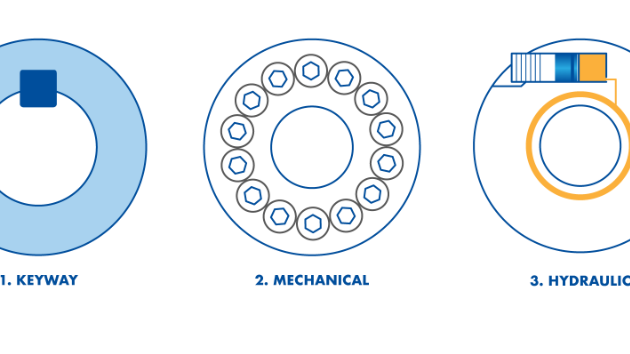

How it works?