News -

Machine tool Industry benefiting from hydraulic connections

Coventry Engineering Case Study

Coventry Engineering is a UK-based engineering firm specializing in the manufacture of bespoke tooling solutions. It has been using couplings and hydraulic connection components from ETP since 2012. Here, Paul Pickering, Operations Director at Coventry Engineering, explains how ETP’s expertise has helped them to provide reliable, flexible solutions to better serve their diverse customer base.

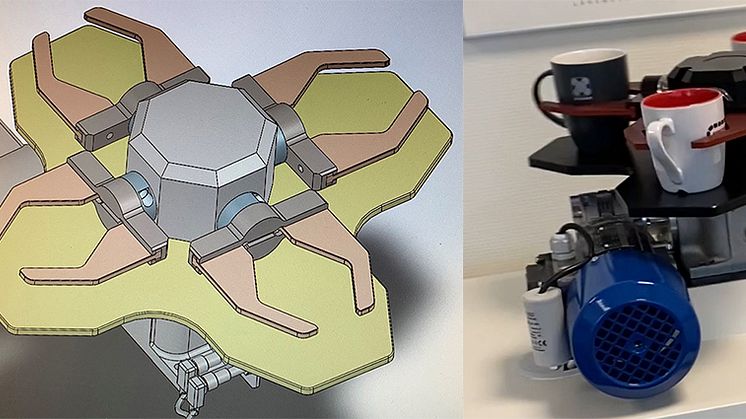

When their customers can’t solve a problem with conventional tooling equipment, Coventry Engineering steps in to provide a tailored solution. Often, this means the development of bespoke attachments that can be fitted to a machine to fulfil a specific application. Sometimes, they need an auxiliary component to give them greater flexibility to meet a customer’s needs - and that is where ETP’s coupling devices really add value.

“ETP gives us exactly what we need to fulfil our contracts with our customers,” Paul says. “For example, if an unmanned machine has an automatic tool selection function, where it picks a tool out of its carousel and carries on working, it needs to have automation and alignment built into it. Historically that gave us a problem with our standard attachments, but the ETP components give us increased flexibility by providing 360-degree rotation of our output position relative to where it needs to fit on the machine. For us, it has been the missing piece of the jigsaw that allows us to meet any customer brief.”

Power and finesse

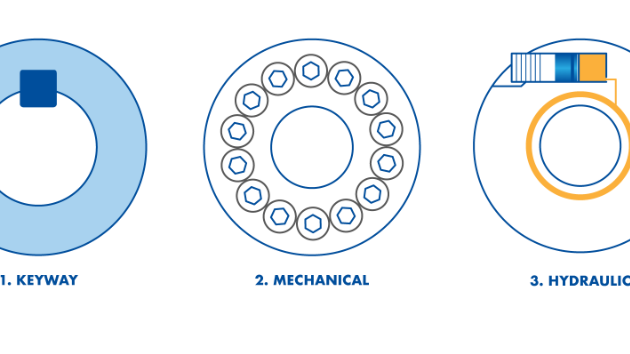

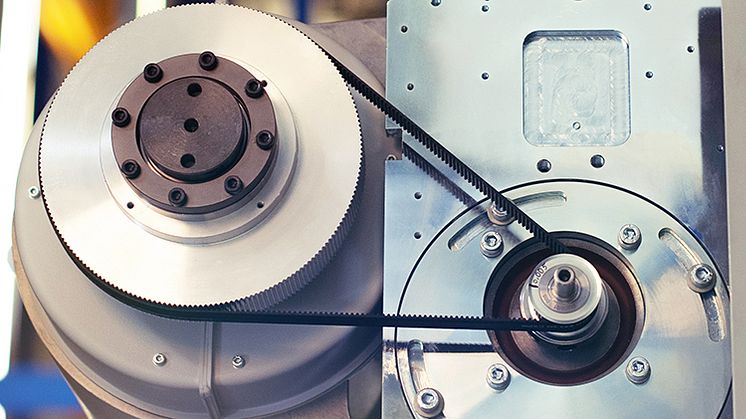

Coventry Engineering typically uses heavier 50mm and 60mm versions of the ETP couplings. The ETP-CLASSIC can be used in a large variety of applications and is easy and quick to assemble, while still offering high precision. It can also be dismantled quickly for simple service and maintenance requirements. For bespoke applications, the Coventry team uses ETP-TECHNO - which is a hydraulic connection with very high precision.

“The ETP CLASSIC is used for all our standard products,” Paul says. “It is simple and cost-effective, and it gives us the ability to stay competitive. We use the ETP-TECHNO range for all our bespoke, heavier duty requirements. It can transmit a lot of power, but also has the finesse to handle intricate and accurate tooling applications.”

Taking the impact

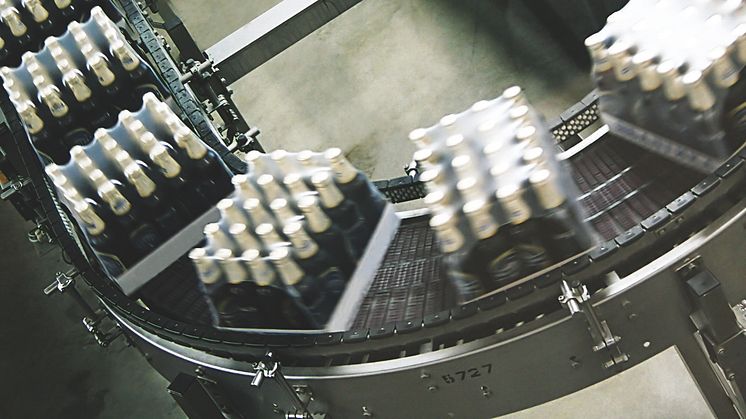

Coventry Engineering’s customers operate across a range of industries, including heavy duty manufacturing settings such as excavation equipment, where hugely powerful machines are operating. In these settings, the machines often are capable of transmitting much more power than Coventry’s standard attachments can handle. One of the biggest benefits of the ETP-TECHNO connection is that it is capable of transmitting much more power and torque. As such, it works like a clutch or overload device, taking the risc of damage away from the machine itself - as well as Coventry’s precision attachment.

“We use the ETP-TECHNO component as a breakpoint,” Paul says. “Without it, any excess power surge would inevitably result in broken gears or bent shafts. Now, the ETP part absorbs the impact of the extra power and keeps spinning, preventing any potentially costly damage to either our customer’s host machine tool or our attachment. It is a huge selling point for us.”

Knowledge and experience

Coventry Engineering deals primarily with ABSSAC - a long-standing partner and supplier of ETP in the UK. Paul says their enthusiasm and expertise has been extremely useful in ensuring they get the best out of the ETP products.

“They are really helpful and keep us informed about new products in the range and any applications they have seen that utilise the components well. A lot of suppliers just pay lip service to the products - all they want to do is sell. But we have found a professional relationship with ETP and ABSSAC that suits our needs perfectly. Customers are always pushing the boundaries, looking for accuracy gains or to transmit more power. We now feel confident we have the flexibility to meet any brief that a customer may have.”