News -

Nobody cuts it better

"Made in Austria" as a Hallmark of Quality

STM Waterjet Group has been setting the standard in water jet cutting technology for over twenty years. With a commitment to precision and durability, 60% of STM’s systems cater to the premium segment, incorporating high-quality, stainless steel ETP-EXPRESS hydraulic locking bushes.

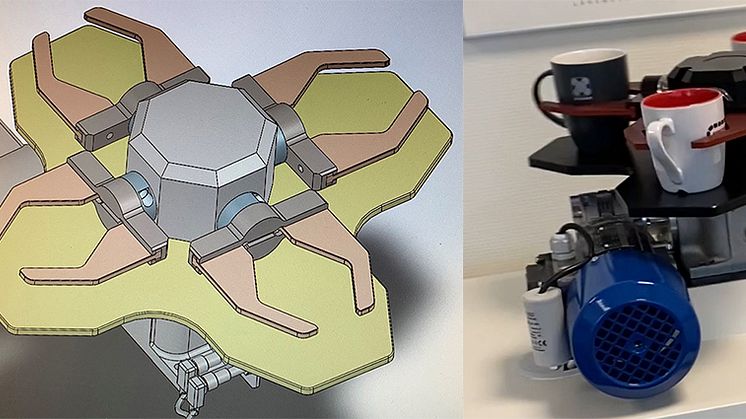

STM’s customers know they are getting cutting-edge technology, backed by ongoing research collaborations with universities and the Fraunhofer Institute. As Head of Development & Project Management, Sascha Baumann ensures the continuous evolution of STM products, focusing on quality and innovation. STM’s clients range from major global players like Ford and ThyssenKrupp to smaller metalworking and medium-sized companies worldwide.

Delivering Maximum Process Reliability

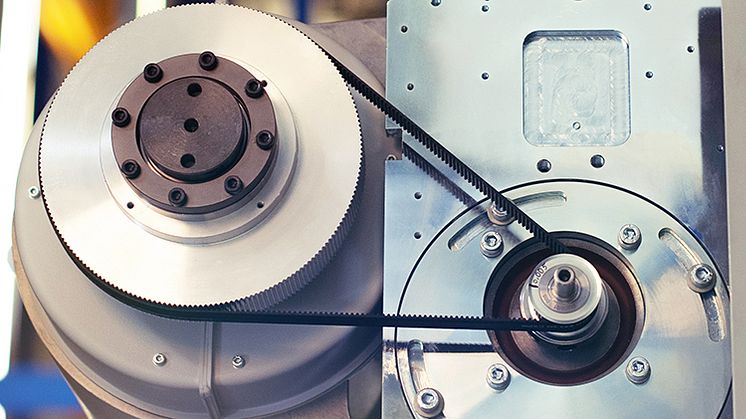

In water jet cutting systems, quality components and expert craftsmanship are paramount. A prime example is the MasterCut, built for demanding tasks, featuring a lightweight aluminum and stainless steel frame and operating at pressures up to 6,000 bar. STM Waterjet Group has partnered with ETP for over a decade to ensure consistent quality, even under high pressure.

“We install four ETP-EXPRESS stainless steel hydraulic locking bushes in our premium products and have relied on ETP’s quality for the past ten years,” says Sascha Baumann.

Effortless Assembly

Each component of STM’s systems must not only meet exacting standards but also be simple to assemble and maintain. The ETP-EXPRESS bush, which requires only one screw for installation, simplifies the process, allowing reliable functionality even after repeated use. It is also easy to clean and maintains performance in extreme temperatures, from -30 to 85 °C.

“Assembling the ETP-EXPRESS stainless locking bush takes only one screw – nothing can go wrong,” Sascha Baumann explains.

A Commitment to Sustainability

For over a decade, ETP has placed sustainability at the core of its operations. By gathering data from our internal processes, we’ve developed a measurable indicator for our products' environmental impact. The ETP-EXPRESS, for instance, has an environmental footprint equivalent to that of a Big Mac. However, unlike a Big Mac, the ETP-EXPRESS is fully recyclable—its stainless steel can be melted down and repurposed into new products after years of use. This commitment to sustainability aligns with STM’s values and reflects a shared vision for long-term environmental responsibility.

The ETP-EXPRESS stainless steel hydraulic locking bush offers consistent runout and is emblematic of ETP’s mission to “help customers achieve excellence through simplicity.” This shared dedication to quality and sustainability forms the foundation for a lasting partnership between STM and ETP.