News -

ETP Transmission introduces a new concept solution in automation

ETP Transmission introduces a new concept solution

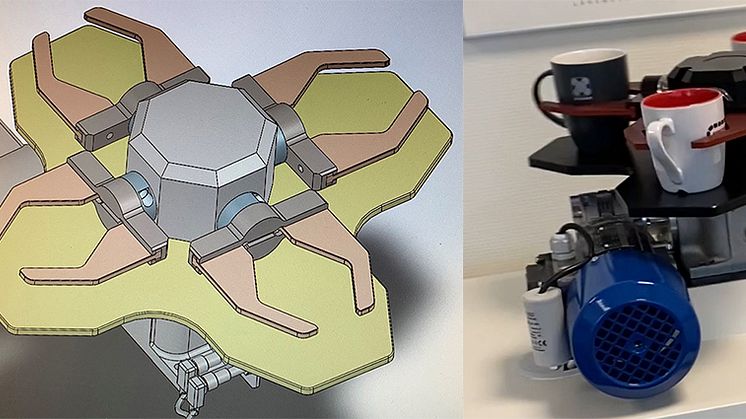

In collaboration with MFAB and Bengtssons Maskin ETP Transmission AB has created a new concept solution within automation. The solution partially consists of the hydraulic connection – ETP-EXPRESS.

– What’s especially unique about ETP-EXPRESS is that it’s an extremely small connection that does a very big job, says John Haglund, reseller of ETP Transmission at Bengtssons Maskin.

In the beginning of 2020 last year, the reseller of ETP Transmission AB, Bengtssons Maskin, began working on a solution for expanding the usage of ETP-EXPRESS together with Maskinkonstruktion Finnvedens AB. The idea was clear from the beginning - the solution had to be related to the fields that the companies’ operates in. The challenge was to come up with a reality-based solution that had advantages compared to existing solutions, and already after a month the ETP-connections had been integrated into a new concept solution. During this period of time a prototype for display had also been developed for Bengtssons Maskin.

– We managed to find a new area of usage for the ETP-connections within automation.

What’s particularly unique about the concept solution is that the ETP-connections create a fast, simple and economical way to switch between, for example, different grippers on a robot, says Kent Bengtsson, CEO of Maskinkonstruktion Finnvedens AB.

More about ETP-EXPRESS

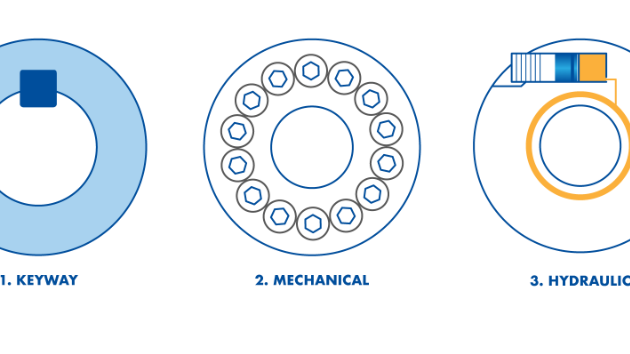

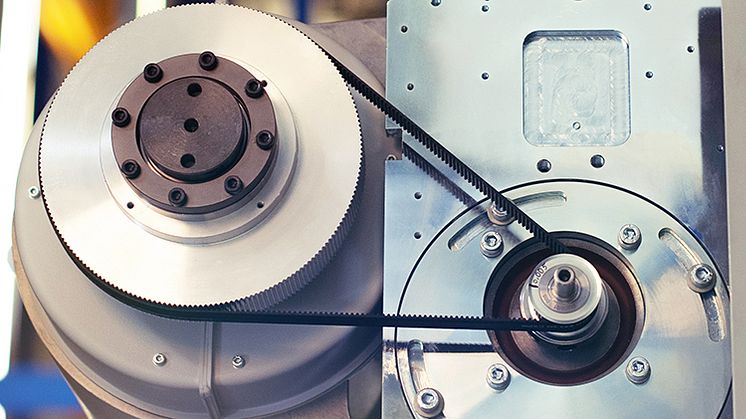

ETP-EXPRESS is a hydraulic connection that consists of a double-walled hardened steel, the connection is suitable where quick and precise positioning of the hub is needed. Before the area of usage was expanded to include automation the usage of ETP-EXPRESS was mainly in a motor shaft, for instance the connections were used in handling and packaging machines for newspapers after printing. ETP-EXPRESS was especially useful and suitable for the final adjustment of levers and timing pulleys, as only one screw needs to be loosened or tightened which makes the entire process both faster and smoother. When pressurising, the screw is tightened which makes the double-walled sleeves expand uniformly against the shaft and hub which creates a rigid joint. Kent Bengtsson underlines that since the connection now is able to be used within automation it is advantageous by several aspects.

– “It’s a great product that will be a lot cheaper as a solution within automation compared to many others. It’s a small and compact product that’s packed in a slim design”, finishes Kent Bengtsson.

To see the concept solution click here.