News -

The evolution of Hub-Shaft connections

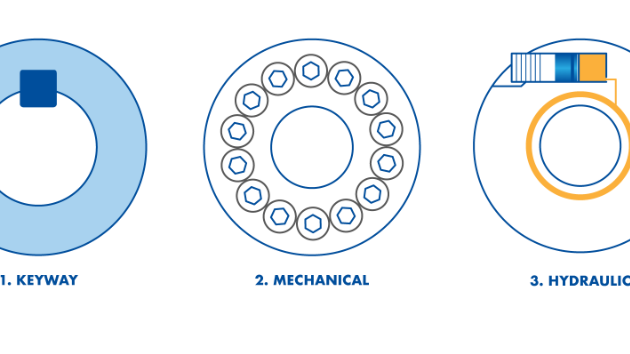

Today three major solutions are commonly used in the hub-shaft connections industry. This article presents the basics of each technique, starting with Keyway connections.

Keyway connections

A keyway connection consists of a slot cut in a shaft component, receiving part of a key that engages with an equivalent slot on a mating hub component, locking the two parts together.

Whilst keyways are cheap to produce and well standardized, disadvantages include;

- Disadvantageous for mounting, dismounting and adjusting

- As forces are concentrated around a small area, bigger shafts are needed to transmit torque, which results in over dimensioning

- Increased unbalance and weaker precision of mounted shaft and components

- Prolonged, meticulous assembly required, as the exact location of the keyway

needs to be established

- Keyways weaken shafts, causing an increased risk of fretting, fatigue and breakage

Mechanical clamping connections

Mechanical clamping connections consist of two sleeves with tapered surfaces that are pressed against each other along the shaft. Many screws with high tightening torque are used to hold it together. When mounted the two sleeves deform into contact with the bore of the hub and the shaft. This technique is used in rough applications where surfaces finish and tolerances are variable.

Whilst this standard connection is suited for transmitting high radial loads, bending torque and can withstand temperature variations, disadvantages include;

- Sleeves move axially, making hub positioning difficult

- Use of high tightening torque on screws to overcome internal friction forces

on tapered sleeves

- Difficult to get a good runout. Screws must be tightened evenly and in a certain pattern

- Special dismantling screws are needed to overcome internal friction between sleeves and to release the connection

- Disadvantageous for mounting, dismounting and adjusting

Hydraulic clamping connections

Hydraulic clamping connections enable effortless mounting, adjustability, easy reach and a well balanced design. The technique is a problem solver for critical applications. ETP hydraulic clamping connections are beneficial for working with tight tolerances, resulting in superior runout.

To expand your knowledge of ETP’s hydraulic solution, let’s begin with the principle from which our products originate:

Pascal’s principle

French scientist Blaise Pascal devised the maxim of pressure propagation in liquids during the 17th century. The principle refers to pressure changes in liquid within a confined container where pressure transmits evenly throughout the liquid. When applying pressure at one point of the liquid, an even pressure change occurs around the whole container.

ETP Principle

ETP hub-shaft connections are guided by Pascal’s principle. Our products consist of hardened double walled steel sleeves. The sleeves are welded together to create a hollow chamber and the inside is filled with a hydraulic pressure medium.

How it works

By the low force of your hand tightening the screw, an internal pressure of approximately 1000 bar is created. This causes the sleeves to expand evenly in all directions around the hub and shaft. The result is an even surface pressure and a secure and precise connection between the hub and shaft.

By using the ETP principle our products presents you with a number of advantages compared to other solutions;

- Easy and accurate positioning along the shaft, as no axial movement occurs

- Mounting and dismounting is done in seconds

- Excellent runout as the connection self-centers.

- Compact, with small built-in dimensions

- Free space along the shaft as no dismantling screws or special tools are needed

Summary

Hydraulic connection: consists of hardened double-walled steel sleeves filled with a hydraulic pressure medium. With a single screw, pressure builds up around the hub and shaft to form a secure connection.

Keyway connection: consists of a slot cut in a shaft component that receives part of a key that engages with an equivalent slot on a mating hub component, locking the two parts together.

Mechanical connection: consists of two sleeves that have tapered surfaces. With the help of screws, the sleeves deform, creating pressure when coming into contact with the bore of the hub and the shaft.

ETP motto: Quick, Easy, Precise

ETP is the only company manufacturing hydraulic hub-shaft connections in a standard range.

ETP hydraulic connections create an even surface pressure around the hub and shaft.

Mounting and dismounting of ETP connections are performed in seconds.

ETP hydraulic connections give you excellent runout as they are self-centering.