News -

ETP-CLASSIC - Where it all started!

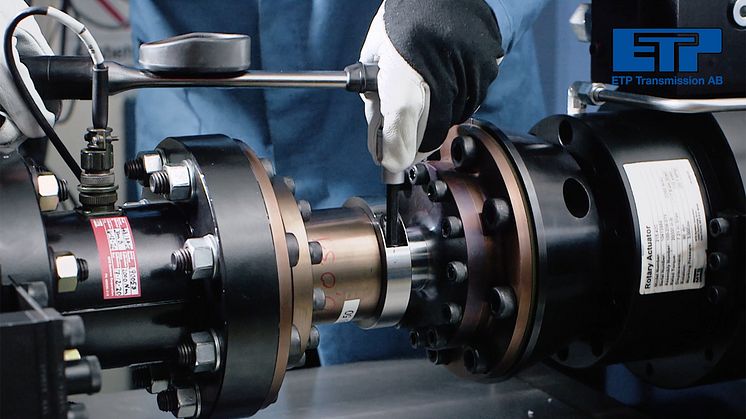

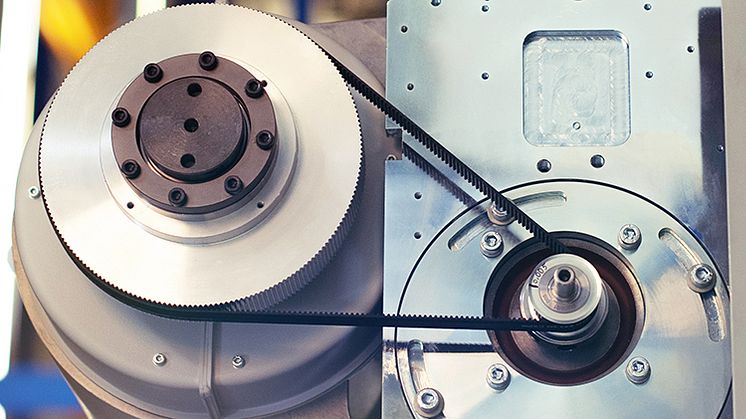

ETP’s original product, ETP-CLASSIC, is a hydraulic connection consisting of a hardened, double-walled steel sleeve containing a specially developed pressure medium, sealing ring, piston, pressure flange and cap head clamping screws.

Operation: When tightening the screws, the sleeve expands uniformly against the hub and shaft, creating a rigid joint. The screws are tightened in consecutive order, approximately one half-turn at a time, until the required tightening torque is achieved. When loosening the screws, also in consecutive order, half a turn at a time, the sleeve returns to its original measurements and can easily be dismantled.

Advantages

- A robust and cost-effective connection.

- Fine adjustment of the hub can be made during mounting.

- Low tightening torque and a small number of screws makes mounting easy.

- Good concentricity, also after several mountings.

ETP-CLASSIC is available as a standard for shafts 15 – 100 mm and in additional imperial sizes.

Runout is 0,03 – 0,06 mm depending on shaft size.

Maximum number of mountings is 100.

ETP-CLASSIC TYPE R

The most common sizes of the hydraulic connection ETP-CLASSIC are available in a stainless steel version, called Type R.

The stainless steel version has the exact same function, built-in dimensions and benefits and features of the standard ETP-CLASSIC. However Type R has a few more clamping screws, as the allowed tightening torque of stainless steel screws is lower, resulting in a reduction of the transmittable torque by approx. 20%. The screw lubricant is also approved for use in the food industry.

Hex head clamping screws make cleaning easier.

Type R Advantages

- All parts exposed to the environment are made of stainless steel.

- Screw lubricant is food industry approved.

- ETP-CLASSIC TYPE R has the same benefits and features as ETP- CLASSIC.

ETP-CLASSIC TYPE R is available as a standard for shafts 15 to 50 mm.

Runout is 0,03 – 0,06 mm depending on shaft size.

Number of mountings possible is 50.