News -

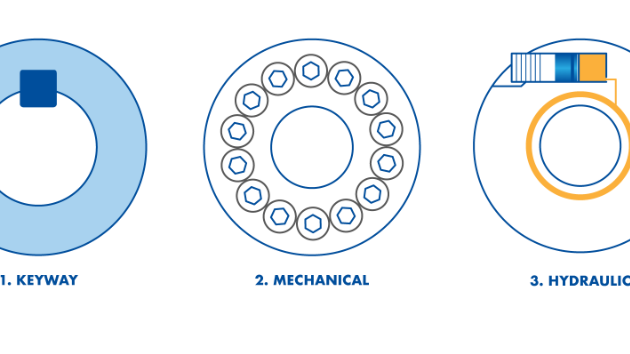

Hub-Shaft connection for quick and accurate mounting

ETP-EXPRESS functions as a hydraulic connection, operating with a single screw for pressurizing. The result? Quick mounting, dismantling, as well as hub repositioning and adjustments, that can all be easily performed with impeccable accuracy.

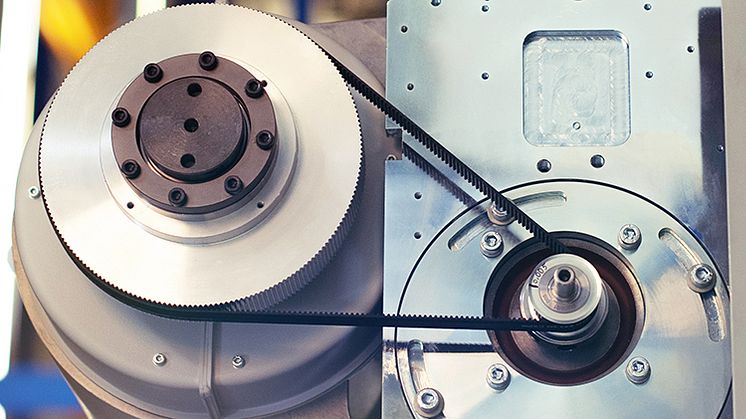

Quick mounting and compact design

Construction: ETP-EXPRESS consists of a double-walled, hardened steel sleeve, filled with a pressure medium, and a flange part containing a pressure screw and piston with seals to maintain pressure.

Operation: When the pressure screw is tightened, the sleeve expands uniformly against the hub and shaft and creates a rigid joint. Dismantling is done simply by loosening the screw. ETP-EXPRESS then returns to its original dimensions and can be easily dismantled.

Advantages

Enables shorter assembly times and increased productivity, as only one screw is needed for mounting the connection.

Compact and thin design enables the use of smaller hubs which allow for a more compact machine design.

Allows precise synchronization with additional machine elements quickly and easily.

No axial movement. When pressurized, does not change position along the shaft, as the sleeves only expand radially.

Technical specifications

ETP-EXPRESS is available as a standard for shafts 15 – 100 mm and in additional imperial sizes.

Runout is ≤0,02 mm.

Number of mountings possible is 500 to 2000 depending on shaft size.

ETP-EXPRESS TYPE R

The most common sizes of the hydraulic connection ETP-EXPRESS are available in a stainless steel version, called Type R. The stainless version of ETP-EXPRESS has the exact same function, built-in dimensions, benefits and features as the standard ETP-EXPRESS.

All parts exposed to the environment are made of stainless steel.

Type R Advantages

Flat flange design allows for easy cleaning.

Pressure medium and screw lubricant are food industry approved.

ETP-EXPRESS TYPE R has the same benefits and features as ETP-EXPRESS.

All parts exposed to the environment are made of stainless steel.